The marine propulsion of tomorrow

Powerful, automated, zero-carbon

Using directly the power of wind to assist your ship's engine, our wing-sails generate considerable fuel savings and allow you to face the IMO regulations (EEDI, EEXI,...).

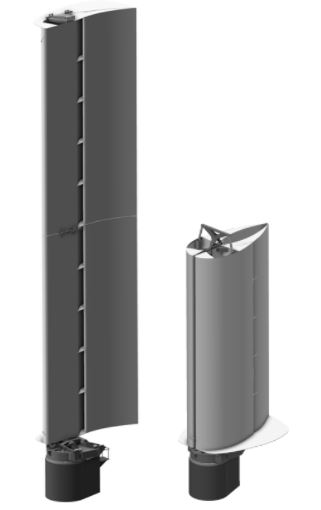

The perfect shape

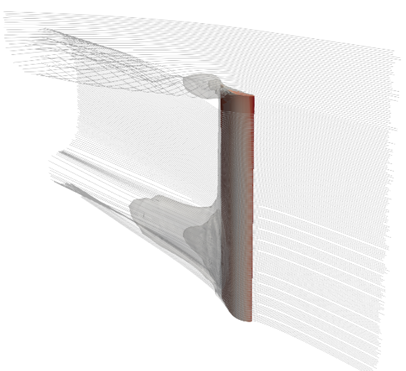

Our patented technology allows us to design a thick, assymetrical wing-sail able to change tack to use port and starboard winds.

The exceptional lift-to-drag ratio allows it to use wind power by almost all wind conditions, including on fast ships.

A patented inversion system

The wind engine check list

- Powerful : The best possible lift/drag ratio (>11) : the wing of a glider

- Robust : Composite surface and structure like a wind turbine = durability for m2 ; Linkages : only pivots + locks = proven technology from offshore tech

- Simple : Height reduction (/2) + aerodynamic force reduction (/10) + increase in strength (x4) … in one step

The optimal trim

Our system is able to tune itself automatically depending on the wind conditions to ensure optimal savings on our ship.

The exceptional lift-to-drag ratio simplifies the integration with existing hulls and propulsion systems, giving twice the performance of a symmetrical wing-sail of the same size.

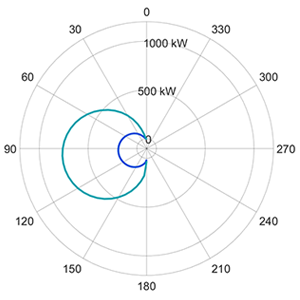

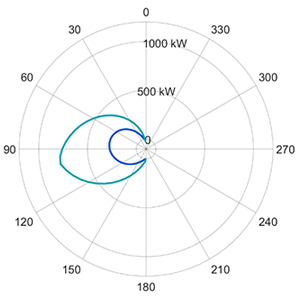

The maximum power

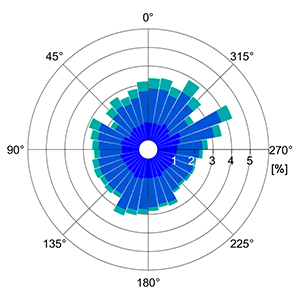

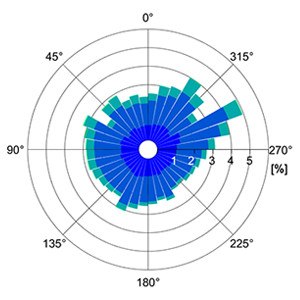

On a ship sailing 16 knots, even the Atlantic winds are rarely at broad reach.

That's why the performance very close to the wind (20° apparent wind) is so important.

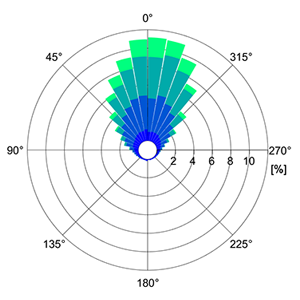

True wind

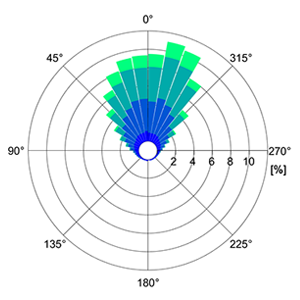

Apparent wind

Statistics US > Europe

Statistics Europe > US

Propulsion power

Full performance for your ship

CWS is working with several partners to provide the most accurate performance predictions for our wing. This includes full 3d wind tunnel testing, ship balance analysis, EEDI reduction analysis and operational fuel economy through optimized routing.

We can also work with several third-party modeling companies in order to provide you with an independent validation of our system.

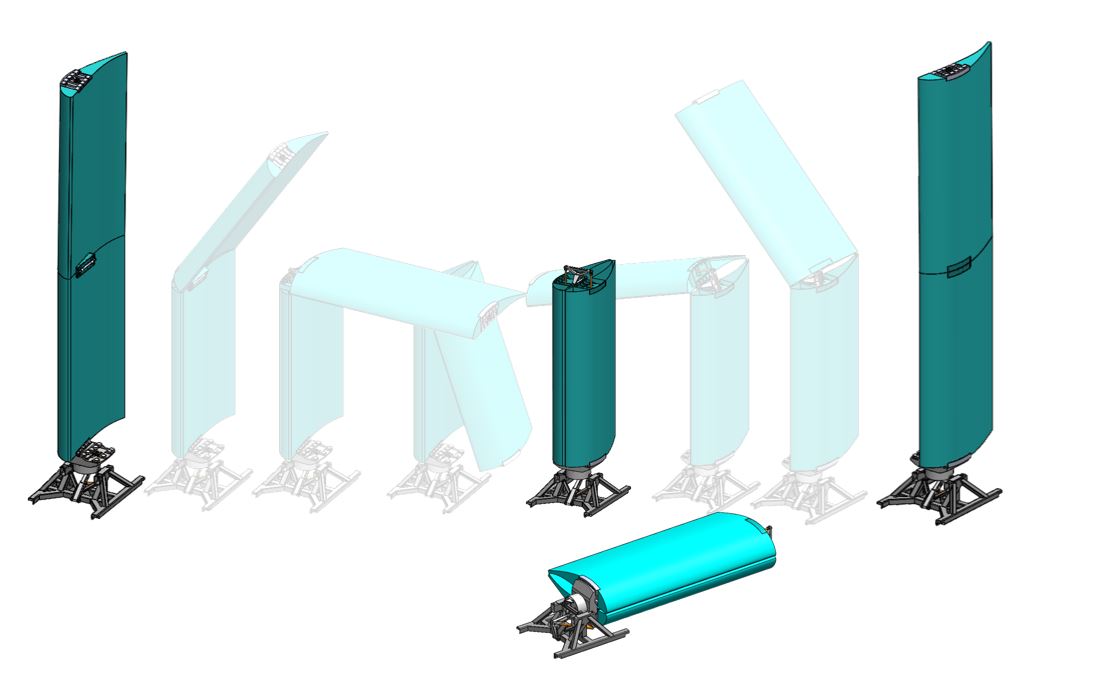

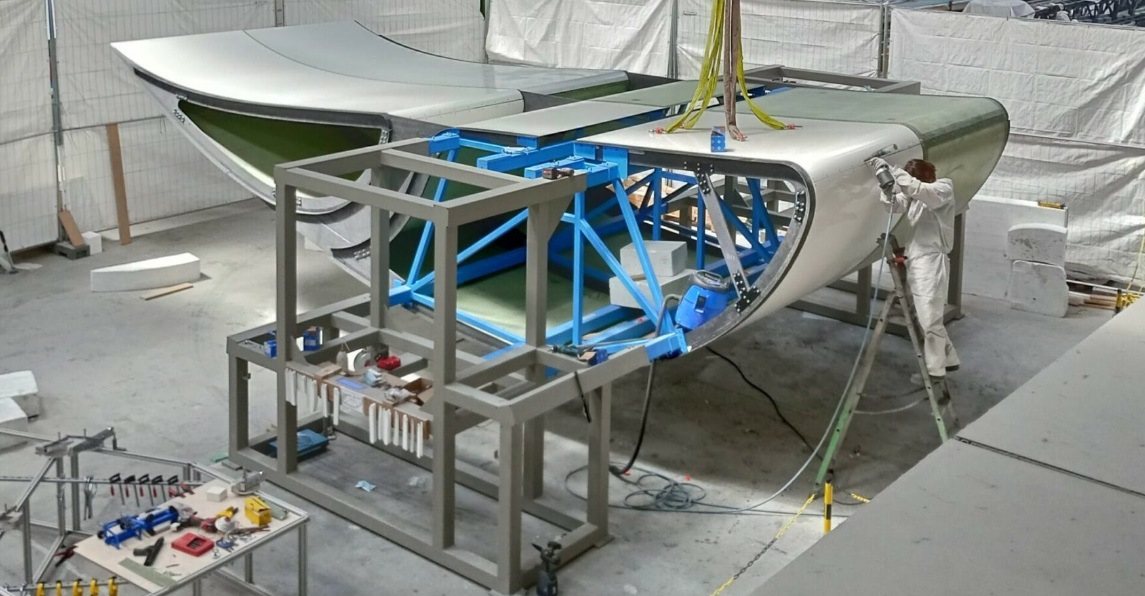

Mastery of manufacturing steps

Low interface

A-frame on its way

Section being assembled

Prototype ready to be tested

Diva

Lying position

Elevated position

A motivated and enduring team

2018 : First prototype presentation

2024 : first factory in Saint-Nazaire (FRANCE)

A versatile system fitting all ship types

-

- - Optimal performance at all cruise speeds

- - Greater savings on realistic wind conditions

- - Significant reduction of air draft

- - Various integration options

LNG tankers

Container ships

Ro-Ro or Ro-pax

Know your ship and start saving now !

EEDI and EEXI constraints are one of the main preoccupation of shippers. Thanks to our partnership with Adrena and working in collaboration with MARIN, D-Ice and Blue WASP we can provide you with not only a historical assessment of what a CWS installation would provide … But also the savings you can start achieving right now using routing software on your ship.